Schmittparts Exchange Crankshaft Part No 0004-Bosch

Developed and refined by specialist German Engineers featuring many improvements over the original Sachs design. These are aimed particularly at improving the reliability and durability of the various moving parts. Only the counterbalance weights are re-used from the original crankshaft, all other parts are new.

Exchange parts terms and conditions

We accept your old crankshaft in any condition including rust damaged. Only the counterweight forgings are re-used as all other parts are new. No exchange – no problem! We can offer a complete crank with compression plates with a nominal surcharge of GBP97.

Compression plates

You must remove the compression plates from your original crankshaft. These are pressed metal plates covering the crankshaft counterbalance weights and their purpose is to reduce the air-space in the crankcase to increase the crankcase compression.. To remove them, gently prise up the edges that secure the pressings to the counterbalance weights using a blade or small screwdriver. Avoid bending the pressing because it will be difficult to straighten later and may foul the crankcase. If you are not confident enough to do this, we can offer compression plates fitted for a small extra cost.

Precision alignment

Crankshafts are precision aligned before the two sides are pressed to secure the crankpin into the taper counterweights. Care must be taken to ensure that the alignment is not disturbed by dropping or poor handling when fitting the compression plates.

Shipping precautions

Special packaging is essential to avoid alignment defects so additional protective packaging is added for shipping.

Bearings and seals

We also offer main bearings and main bearing seals on our website.

Technical description

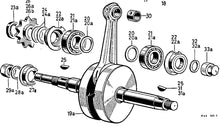

The forged steel connecting rod has a much stronger roller bearing assembly fitted to the big end. A roller bearing small end bush is fitted. This is retained by a plastic tie wrap for transit but is fully floating after assembly. The technical details are as follows:-

New precision ground taper shaft for mounting the flywheel with correctly machined keyway.

New precision ground drive side shaft including harder material for the camshaft.

Larger big end bearing assembly with lower lubrication requirement.

Roller bearing small end (with part No. 0003a)

New cam as - original smooth ground finish for long contact breaker life.

Camshaft end drilled and tapped M4 to facilitate retention of electronic ignition timing flag.

Caution, never fit main bearing inners without at least 1mm shim behind. It is almost impossible to remove the bearing as no gap is available to fit the extractor jaws. It is easier to set up the crankshaft shims if the compression plates are left off until final assembly.

Reliability

There have been no reported instances of failure since the introduction of these new crankshafts. It should be noted that earlier German supplied crankshafts did not include the new cam offered as standard on current stock.

Extra care if you have an Original Sachs Crankshaft

It can be very expensive to neglect the original old crankshaft. All are now more than sixty years old and many have pitted or rusty big end bearings. These can fail with catastrophic results, often destroying the engine. You have been warned!

Comparison of Steel and Aluminium connecting rod.

The original Sachs connecting rod is fabricated from Aluminium alloy. It is lightweight and has smooth rounded contours to aid gas flow at high engine revolutions. One disadvantage is that, in case of catastrophic failure of the big-end bearing, the bearing housing tends to peel apart and the remaining connecting rod smashes through the gearbox. This often damages the crankcase castings beyond repair. Some Messerschmitters believe the original type is capable of higher revolutions than the alternative steel type described below. The reciprocating weight of the connecting rod and piston are counterbalanced by the crankshaft counter weights. It is not possible to completely counter the forces of the piston and connecting rod at all engine revolutions and the chosen amount of counter-balance is always a compromise.

New design steel connecting rod with roller bearing small end

The new forged steel connecting rod is considerably stronger than the original aluminium type. There have been no reported failures since introduction of this type so we do not know how it behaves when the bearing fails. However, the modern design does tolerate a much lower petrol to oil ratio and the stronger design would reduce the risk of catastrophic failure described above for the aluminium connecting rod. The roller bearing small end is a significant advantage in reducing friction, again contributing to the ability to run weaker oil to petrol ratios. There is a small weight penalty and the steel rod is not as smooth in contour as the aluminium type.

Bosch and Siba type crankshafts - Explanation of differences.

Siba crankshafts have two types.

Up to 1956, identified by big end bearing without lubrication slots.

Post 1956, identified by four lubrication slots visible around the connecting rod main bearing. Flywheel is light brown colour.

Take care not to confuse these with the Motorcycle versions which have a 20 mm diameter main bearing shaft diameter, (I believe some of the 1955 KR200s had this type though I have never seen one). All have 25mm main bearing shaft diameter. The distance between the crankshaft bearing mounting faces is nominally 45mm. The actual dimension, as built at the factory, is etched into the side of the connecting rod. This is intended for use in calculating the number of shims when assembling the engine.

Bosch crankshafts are identified as follows:-

Fitted to KR200s from late 1958 with Bosch dynastarter. The distance between the crankshaft bearing mounting faces is nominally 50mm. The actual dimension, as built at the factory, is etched into the side of the connecting rod. This is intended for use in calculating the number of shims when assembling the engine.

The crankshaft has a 1:7.5 taper for the dynastart mounting with a standard keyway. Flywheel is light green colour.